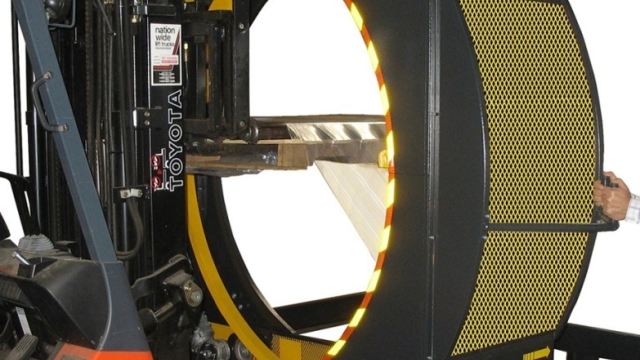

Welcome to the world of packaging efficiency! Today, we uncover the wonders of the ultimate stretch wrapper that is set to revolutionize the way products are packaged and shipped. The pallet wrapping machine, also known as the pallet wrapper or stretch wrapper, is a game-changer in the world of packaging technology. With its innovative design and functionality, this stretch wrap machine brings unprecedented levels of efficiency and convenience to companies of all sizes.

Picture this: a warehouse bustling with activity, where products are carefully organized on pallets, awaiting their journey to retailers and customers alike. Enter the stretch wrapper – a magnificent machine that takes these pallets and expertly wraps them in a layer of stretch film. This film securely holds the products together, preventing shifting, damage, and tampering during transportation.

But why is this pallet wrapping machine considered the ultimate solution? It boasts a host of advanced features that simplify and streamline the packaging process. The stretch wapper’s automated operation saves time and minimizes human error. By precisely calculating the required film length and tension, it optimizes material usage, reducing waste and ultimately cutting costs. Moreover, its adjustable settings cater to various product sizes and shapes, ensuring a snug and secure wrap every time.

Intriguing, isn’t it? Join us on this captivating journey as we delve deeper into the fascinating world of the stretch wrapper and explore how this incredible machine is revolutionizing the packaging industry. Get ready to witness firsthand the unrivaled efficiency, effectiveness, and innovation of the ultimate stretch wrapper!

Benefits of Pallet Wrapping Machines

Improved Packaging Efficiency: Pallet wrapping machines, also known as pallet wrappers or stretch wrap machines, offer a significant boost to packaging efficiency. These machines automate the process of wrapping pallets with stretch film, which saves valuable time and reduces manual labor. With precise control over the wrapping tension and speed, pallet wrapping machines ensure consistent and secure packaging, resulting in enhanced overall efficiency for businesses.

Cost Savings: By utilizing pallet wrapping machines, companies can achieve cost savings in multiple ways. Firstly, the automation of the packaging process reduces the need for manual labor, which can help decrease labor costs. Additionally, stretch wrap machines use stretch film more efficiently compared to manual wrapping methods, reducing material waste and providing substantial cost savings in packaging supplies.

Enhanced Product Protection: Pallet wrapping machines play a crucial role in ensuring the protection of products during transit and storage. The tight and secure wrapping provided by these machines minimizes the risk of product damage caused by shifting, toppling, or exposure to dust and moisture. This added protection not only reduces the likelihood of returns or product loss but also contributes to improved customer satisfaction and brand reputation.

Streamlined Supply Chain: Efficient packaging and secure pallets facilitate smoother movement and handling of products throughout the supply chain. By utilizing pallet wrapping machines, businesses can ensure consistency in their packaging, leading to easier handling, warehouse storage, and transportation. This streamlining effect contributes to the overall optimization of the supply chain, reducing delays and improving operational efficiency.

Versatile Application: Pallet wrapping machines offer versatility in their application, accommodating a wide range of product sizes, shapes, and weights. Whether dealing with small or large pallets, irregularly shaped or heavier loads, these machines can be adjusted to meet specific packaging requirements. This versatility makes them suitable for various industries, including manufacturing, logistics, warehousing, and distribution.

Enhanced Safety Standards: Pallet wrapping machines prioritize safety by minimizing the need for manual involvement in the packaging process. By automating the wrapping process, potential safety hazards, such as strains or injuries associated with manual wrapping methods, are significantly reduced. This prioritization of safety not only protects employees but also helps businesses maintain a safer work environment and reduce the risk of workplace accidents.

Choosing the Right Stretch Wrap Machine

When it comes to selecting the perfect stretch wrap machine for your packaging needs, several factors should be taken into consideration. From the size of your operation to the specific requirements of your products, finding the ideal pallet wrapper can drastically improve your packaging efficiency and overall productivity.

Stretch Wapper

First and foremost, you need to evaluate the size and volume of your packaging tasks. Pallet wrapping machines come in different sizes and are designed to handle a specific range of loads. Assessing your average load size and anticipated workload will help determine the appropriate machine capacity for your operations.

Secondly, consider the level of automation that aligns with your packaging requirements. Manual stretch wrap machines require operators to physically apply the wrap to the pallet, while semi-automatic and fully automatic machines offer varying degrees of automation. Analyze the volume and frequency of your pallet wrapping needs to determine the level of automation that allows for optimal efficiency and cost-effectiveness.

Lastly, take into account the specific features and capabilities of the stretch wrap machine. Different machines offer various functionalities such as pre-stretch options, adjustable controls, and film tension settings. Assessing these features in relation to your specific packaging needs will ensure that the chosen pallet wrapper offers the necessary flexibility and customization options.

Remember, the right stretch wrap machine goes beyond its cost – it should be a well-rounded investment that perfectly complements the unique demands of your packaging operations. By carefully considering factors such as size, automation level, and machine capabilities, you can make an informed decision that will revolutionize your packaging efficiency.

Enhancing Packaging Efficiency with Pallet Wrappers

With the continuous advancements in technology, the pallet wrapping process has been revolutionized by the introduction of pallet wrappers. These efficient machines play a crucial role in enhancing packaging efficiency and streamlining the logistics operations of various industries.

Pallet wrappers, also known as stretch wrap machines or stretch wrappers, are specially designed to secure loads on pallets by wrapping them with stretch film. The primary goal of these machines is to ensure the stability and integrity of the palletized goods during transportation and storage.

By automating the wrapping process, pallet wrappers eliminate the need for manual labor and significantly reduce the time required to wrap each pallet. This automation not only improves the overall efficiency of the packaging process but also minimizes the risk of human errors and inconsistencies.

Furthermore, pallet wrappers offer customizable wrapping options that can be tailored to meet the specific needs of different products and industries. The machines allow users to adjust the tension, number of rotations, and overlap of the stretch film, resulting in precisely wrapped pallets that offer optimal load containment.

In summary, pallet wrappers have emerged as a game-changer in the packaging industry, providing a reliable and efficient solution for wrapping palletized goods. With their ability to automate the process, ensure load stability, and offer customizable wrapping options, these machines contribute to enhanced packaging efficiency and improved logistics operations.